Safeguarding Assets: Advantages of Tamper-Proof Screws

In today’s world, where the threat of security breaches is ever-present, fortifying your assets has never been more critical!

Effective solutions such as tamper-proof screws offer a tangible way to prevent unauthorized access and deter potential theft or damage. These specialized fasteners deliver peace of mind, whether they’re installed in public spaces or private facilities. Leveraging the unique head styles and installation requirements, Bryce Fastener has established itself as a leader in crafting innovative security screw systems that address the pressing needs of modern asset protection. By integrating such hardware, organizations can proactively minimize vulnerabilities while also maintaining a streamlined appearance that blends with their existing setups.

Understanding Tamper-Proof Screws

Modern tamper-resistant solutions are designed not only to impede intruders but also to resist harsh environmental factors. Properly deployed, these screws form an essential barrier against opportunistic acts that can lead to costly losses or downtime, highlighting why industries ranging from electronics to automotive have steadily adopted these components.

In addition to their functional advantages, tamper-proof screws present a practical and cost-effective way to enhance overall security strategies, ensuring that your valuable investments and public infrastructure retain their integrity over time. The versatility of design means that, regardless of the scope or sector, an optimal tamper-proof solution is available.

To further understand their creative engineering and specific use-cases, consider how various applications benefit from tamper proof screws, and the challenges they solve in environments prone to vandalism and theft.

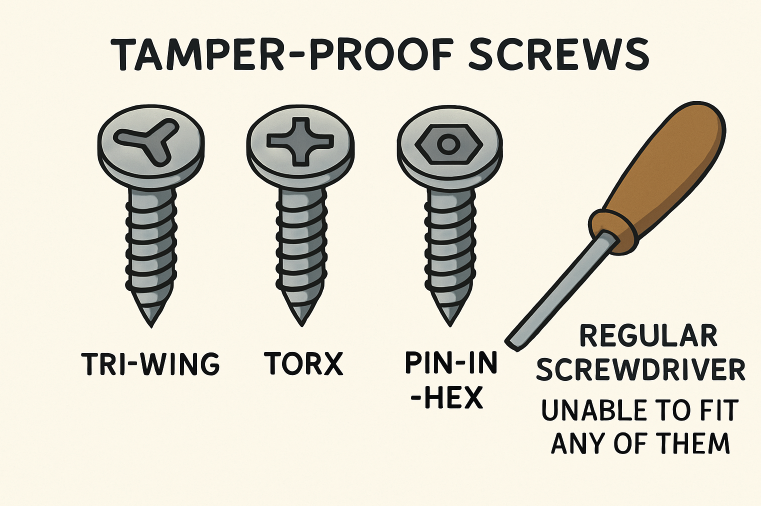

Tamper-proof screws stand out by featuring uniquely engineered head designs that require matching, often proprietary, tools for installation or removal. As a result, standard screwdrivers are rendered useless, effectively foiling quick attempts at unauthorized removal. These features directly address organizations’ concerns over asset security, especially where other barriers may not suffice. According to a report from The Wall Street Journal, incidents of theft and tampering with public infrastructure have surged, underscoring the growing importance of mechanical security solutions, such as tamper-proof fasteners.

Key Benefits of Tamper-Proof Screws

Enhanced Security: With their deliberately complex designs, tamper-proof screws prevent quick disengagement, protecting everything from sensitive electronics to large-scale municipal installations against unapproved access or theft.

Durability: Typically manufactured with resilient, corrosion-resistant materials such as stainless steel or hardened alloys, these screws withstand harsh weather, frequent contact, and wear over prolonged periods.

Versatility: Tamper-proof screws are engineered in a vast array of sizes and profiles, enabling installation across diverse systems and products—from circuit boards and ATM machines to benches, railings, and signs in public parks.

Common Applications

Recognized for their robust deterrent properties, tamper-proof screws are applied in various settings:

- Electronics: Device manufacturers routinely use these fasteners within enclosures, preventing end-users or vandals from tampering with sensitive internal components while ensuring warranties aren’t voided due to unauthorized repairs.

- Public Infrastructure: Municipalities install tamper-proof fasteners in everything from lamp posts to playground equipment, reducing instances of vandalism or sabotage that could compromise safety or functionality.

- Automotive: Access to engine components, license plates, or in-car electronics can be tightly controlled, preventing the theft of high-value vehicle parts and reducing security risks on the road.

The New York Times highlights real-world impacts of metal theft and underscores how robust fasteners are an increasingly essential tool in urban management.

Types of Tamper-Proof Screws

Several distinct types address specific needs in security and usability:

- One-Way Screws: Simple to drive in with the right tool, these screws are extremely difficult to back out, making them ideal for situations where removal is rare or strictly controlled.

- Security Torx: Incorporating a solid central pin, these screws require matched drivers, blocking most standard tools from making contact and turning the fastener.

- Pin-in-Hex Screws: Mirroring the functionality of Torx screws but with a hexagonal recess, these are commonly used in assembly-line settings where both security and speed are required.

Installation and Maintenance

The benefits of tamper-proof screws are maximized only when properly installed. Using the designated driver or tool and adhering to the manufacturer’s torque specifications ensures reliable security and prevents accidental stripping or breakage. Regular checkups are equally important; periodic inspections help you spot signs of attempted tampering, corrosion, or excessive wear. Proactive replacement of compromised fasteners helps maintain the asset’s long-term security perimeter.

Conclusion

The deployment of tamper-proof screws offers organizations and individuals a formidable defense against an increasingly sophisticated array of security threats. Their unique engineering, material resilience, and adaptability make them a staple in efforts to secure assets both large and small. As the challenges of theft and unauthorized access evolve, so too must our approach—empowering security-minded professionals with reliable, tamper-resistant technology that stands the test of time.