7 Things To Consider Before Buying An Air Hose Reel

A well-chosen air hose reel keeps a workspace tidy, safe, and efficient!

It prevents tripping hazards, protects the hose from damage, and saves time during cleanup. Selecting the right air hose reel depends on understanding how different features match the tools, space, and air system in use.

Many people overlook key details before buying one, which can lead to frustration or wasted money. By learning what factors matter most—such as size, pressure rating, and mounting style—it becomes easier to find a reel that fits both needs and budget. This guide explains what to look for so every project runs smoothly and safely.

- Hose length matching your workspace size

A hose that fits the workspace size helps maintain safety and efficiency. A short hose limits reach, while an overly long one can cause tangles or pressure loss. Measuring the area before purchase helps match the reel and hose to the actual distance between the compressor and tools.

A retractable air hose reel offers flexibility for different workspace layouts. It allows users to pull out only the length needed and retract it after use, which keeps the floor clear and reduces wear.

Workshops with large areas may need longer hoses to reach all stations. Smaller garages or home setups often work better with shorter hoses that reduce clutter. The goal is to balance reach and control without wasting air pressure.

Proper hose length also supports tool performance. Air tools depend on steady pressure, and too much hose can drop output. Selecting the right length helps keep operations smooth and consistent.

- Hose diameter compatible with your air tools

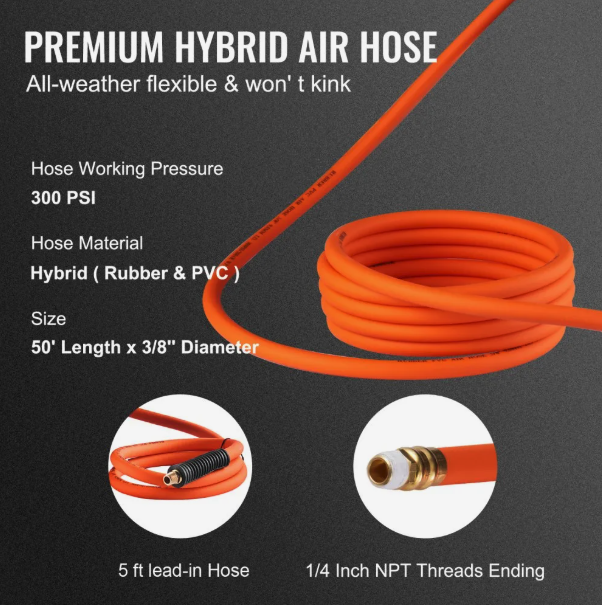

The diameter of an air hose affects how much air flows to a tool. A larger hose allows more air to pass through, which helps tools that need higher pressure or volume work at full power. A smaller hose may limit airflow and reduce performance.

Each air tool has specific air requirements. For example, a spray gun or impact wrench usually needs a wider hose than a nail gun. Matching the hose size to the tool’s air demand helps maintain steady pressure and consistent results.

The air compressor also plays a part. A hose that is too narrow for the compressor’s output can cause pressure drops, while an oversized hose might be bulky and harder to handle. Therefore, users should check both the compressor rating and the tool’s PSI and CFM needs before selecting a hose diameter.

In most setups, 1/4-inch hoses suit light tools, while 3/8-inch or 1/2-inch hoses support heavier-duty air tools.

- Pressure rating suitable for your pneumatic system

The pressure rating of an air hose reel must match the operating pressure of the pneumatic system. A hose rated too low can fail under load, while one rated too high may cost more without added benefit. Therefore, users should check the system’s maximum working pressure before selecting a reel.

Manufacturers usually list both working and burst pressure. The working pressure shows the level the hose can handle safely during normal use. The burst pressure is higher and indicates the point of failure. A good rule is to choose a hose with a working pressure higher than the system’s maximum output.

Temperature also affects pressure capacity. High heat can lower the hose’s strength and shorten its lifespan. Users should confirm that both the hose and reel materials can handle the temperature range of the system.

Proper attention to pressure rating helps maintain safe operation and prevents air leaks or sudden hose damage.

- Material durability for heavy-duty use

A strong air hose reel depends on the durability of its materials. The body, drum, and fittings must handle frequent use, pressure, and outdoor exposure without damage. Metal reels made from steel or aluminum often last longer than plastic ones because they resist wear and impact.

Corrosion resistance also matters. A powder-coated or stainless-steel finish helps protect the reel from rust, especially in humid or industrial settings. This protection extends the reel’s service life and reduces maintenance needs.

The hose material itself affects performance. Rubber and hybrid hoses usually stay flexible in different temperatures and resist cracking better than standard PVC. As a result, they perform well in both indoor and outdoor work areas.

Buyers should also check the connection points and swivel joints. Solid brass or reinforced steel fittings prevent leaks and maintain air pressure. A well-built reel with durable parts keeps equipment safe and dependable for daily use.

- Mounting style fitting your workshop setup

The mounting style of an air hose reel affects how well it fits into a workshop. A wall-mounted reel saves floor space and keeps hoses off the ground, which helps prevent tripping and clutter. It also places the reel at a comfortable height for quick access.

A ceiling-mounted reel works well in larger spaces or areas with limited wall room. This setup keeps the hose out of the way and allows it to extend directly over a work area. However, it may require stronger anchors and careful installation to handle the reel’s weight.

A floor or bench-mounted reel suits smaller workshops or portable setups. It offers flexibility because it can move if the workspace layout changes. Each mounting option has trade-offs, so users should match the style to their space, tools, and workflow.

Proper mounting improves safety and organization. It also helps the reel last longer by reducing strain on the hose and fittings.

- Retraction type: manual vs. automatic

The retraction method affects how easy it is to store the hose after use. A manual reel uses a hand crank to wind the hose. This gives the user more control and helps prevent uneven winding. However, it can take more effort, especially with longer or heavier hoses.

An automatic or retractable reel uses a spring or motor to pull the hose back in. This saves time and keeps the workspace tidy. It also reduces the chance of tangles or kinks. However, it may cost more and require occasional maintenance to keep the retraction system smooth.

Manual models suit those who prefer simple tools with fewer parts that can wear out. Automatic reels fit users who value convenience and speed. The best choice depends on how often the hose is used and how much control the user wants over the retraction process.

- Storage capacity to prevent hose tangling

Storage capacity affects how neatly a hose fits on the reel. A reel that holds the full length of the hose without crowding helps keep it smooth and easy to pull out. If the hose barely fits, it may twist or fold, which leads to tangles.

A larger capacity reel gives the hose more space to coil evenly. This setup reduces friction and stress on the material. It also helps the hose unwind in a straight line, which saves time and prevents damage.

Buyers should measure the total hose length before choosing a reel. Some reels hold 100 feet of hose, while others handle up to 300 feet. Matching the reel size to the hose length keeps storage simple and organized.

Proper capacity also supports better maintenance. A well-fitted reel allows air to circulate and moisture to escape, which prevents mold and cracking. As a result, the hose stays clean, flexible, and ready for use.

Conclusion

Choosing an air hose reel depends on how well it matches the user’s tools, workspace, and air pressure needs. A good reel keeps the hose safe, reduces wear, and helps maintain a clean area.

Buyers should review hose length, diameter, pressure rating, and mounting style before purchase. Each factor affects performance and safety.

Regular care and correct installation extend the reel’s life and help it work smoothly. By comparing features and materials, users can find a model that fits daily tasks and supports steady airflow.